3D

In the high flow rate of the air flow in the air distribution channels at some special points such as knees, turning sections and Ss due to the prevention of air mixing and severe drop and also the creation of a slow fluid flow inside the channel, from the vanes that change the direction of the air from them to The title of training van is also known and used.

Usually, in order for the air inside the channel to move more easily and smoothly, designers avoid creating L-shaped and sharp corners as much as possible in channeling design and try to change the direction of the channels with an acceptable radius when rotating. But sometimes this is not possible and the forced designer chooses the L-shaped corner channel to change the direction. In order to help the air circulation in the L-shaped corners inside the channel, a training van is used inside the channel.

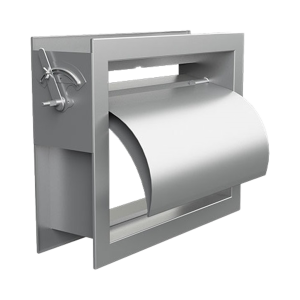

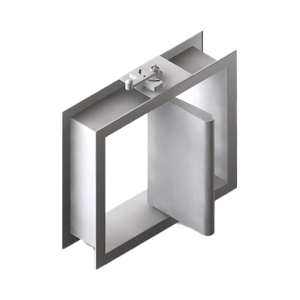

Turning vanes, which are one of the types of industrial dampers and air guides, are installed at the points where the channel changes direction in the form of a 90-degree L-shaped bend and help the air flow inside the channel without hitting the front wall, which leads to pressure drop and disturbance. It becomes too much in the air flow, changes its direction and moves along the channel at a 90 degree angle compared to its previous position.

Dimensional restrictions: at least 50 x 30 cm, and if larger dimensions are needed, it will be made in several pieces and rails.

Material limitations: There are galvanized iron, aluminum, carbon steel and steel constructions.

Installation conditions: When placing an order, the height of the channel and the 90-degree bend of the channel should be taken into account. The training vans are precisely installed on the 90-degree bend of the channel. The installation of training vans is done by screwing the base of the vanes on the channel. In the place of installation (knee tendon) there should not be any protrusion due to the connection of flanges.

Testing capability: It is possible to measure the pressure drop applied in the system by training vans based on national standards ISIRI 7693 and ISIRI 7695 and international standards ISO5219 and ISO5221 in the laboratory of Shahrokhi Technical Institute.

Final coating: This product is similar to manual channel damper and reciprocal motor, degreasing through washing in the soda tub and filling of this type of product is possible. It is also possible to paint according to the customer’s instructions. Epoxy, polyurethane and powder colors are applicable for this product.