3D

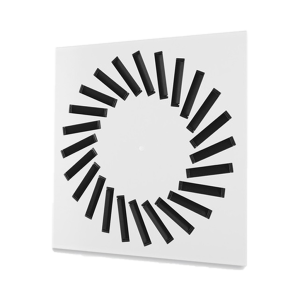

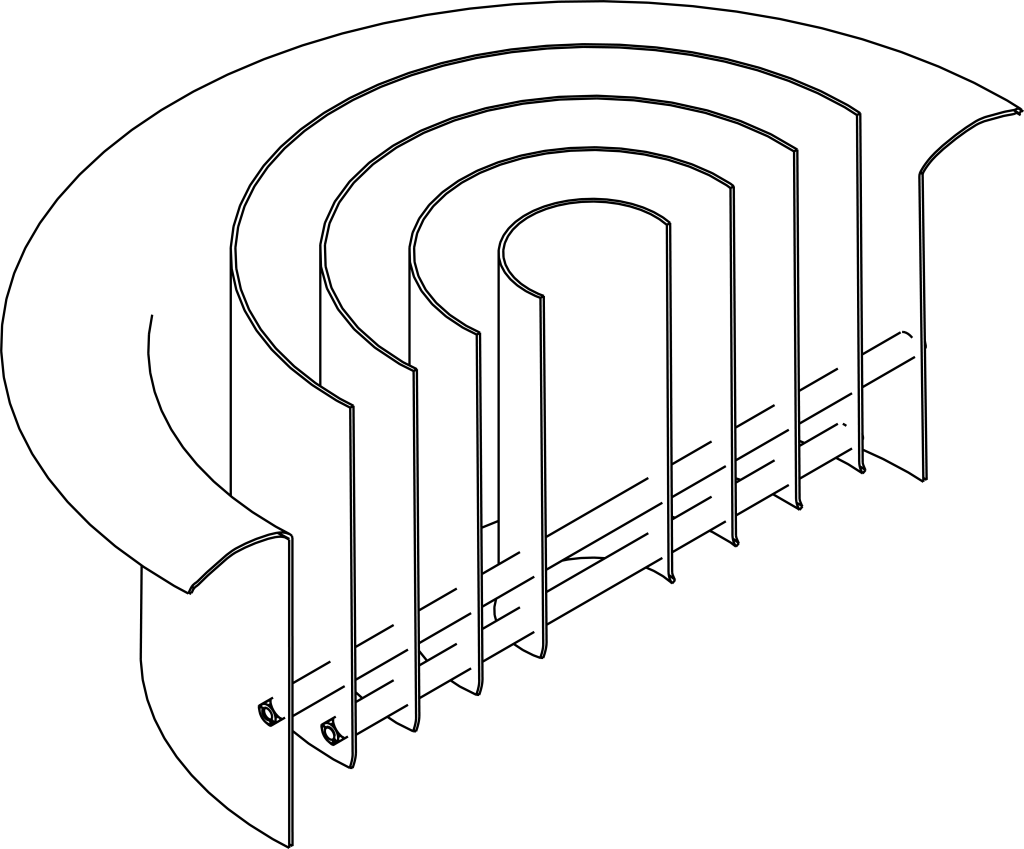

Long throw diffusers are the right choice for spaces where there is a need to transfer ventilated air to far distances from the air outlet. Jet nozzles are designed to throw high volumes of air in large spaces such as production and exhibition halls that require long-throw air. One of the solutions offered by Shahrokhi Technical Institute for high airflow is jet nozzle diffusers that are installed both on the ceiling (vertical projection) and on the wall (horizontal projection).

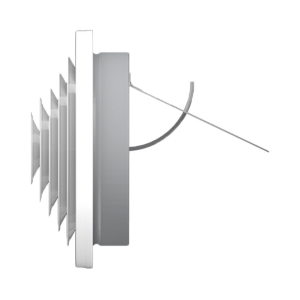

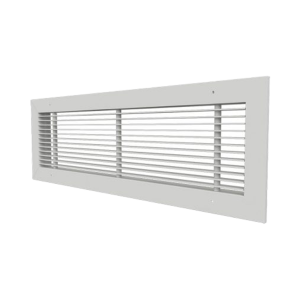

Despite jet diffusers, which can change the flow direction up to 30 degrees in all directions, jet nozzles can change the flow direction up to 30 degrees around one axis only. By using this feature, in addition to the ability to direct the airflow to the desired point, in the cold and hot seasons of the year, it is possible to operate the diffuser according to the direction of the hot wind (downward projection due to the rising nature of hot air) and cold wind (upward projection due to descending nature of cold air).

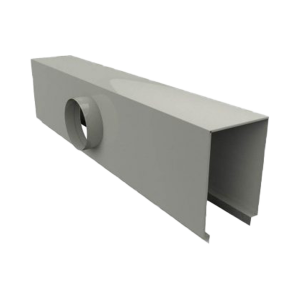

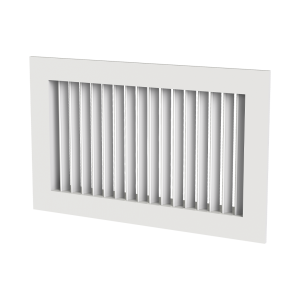

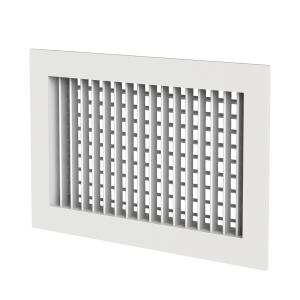

One of the capabilities of these diffusers is to provide it in square elements made of high-quality aluminum sheet in the form of one element to four elements, which provide the ability to inject a large volume of air into the environment. These diffusers are provided in standard nominal diameters of 100, 150, 200, 250, 300, 350, 400, 450, and 500 mm and ventilation direction from 54 to 1440 cubic meters per hour with the ability to adjust the airflow direction from -30 to +30 degrees.

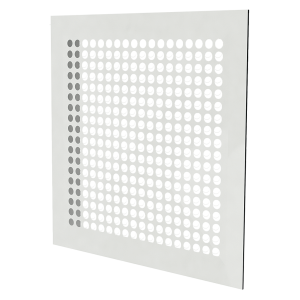

To install the air distribution diffuser of this product, an automatic screw is used, and the screw placement is created before applying the coating on the diffuser frame. Additionally, it is better to install this diffuser on a wooden or metal frame, because if the valve is installed directly on plaster, there is a possibility of loosening over time. In addition, to install these products on false walls with dry materials such as gypsum panels, it must be ensured that special false ceiling profiles are used around the opening of the diffuser for strength and reliable connection of the diffuser to the wall.

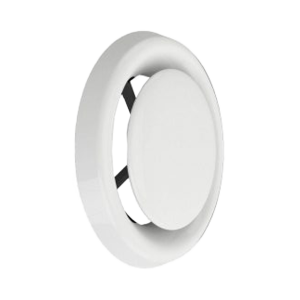

The final coating of these diffusers is electrostatic furnace coating. After carrying out the production steps to remove any grease, dust, and other particles, the valves are acid washed and after applying the desired undercoating (it is selected according to the type of metal and a different coating is used for each type of metal) it is placed on the spraying conveyor line and furnace. After that, the color needed by the customers is sprayed on the surface and the diffuser enters the oven for the baking stage. In the baking stage, the temperature of the oven (the temperature graph that the valve experiences) is very important, and incomplete baking harms the final coating. Additionally, overcooking the paint causes the color to change and become matte.

On 03/06/2012, Shahrokhi Technical Institute succeeded in receiving the license to use the mandatory national standard mark of air diffuser for the first time in Iran, and according to the decree of the National Standards Department of Iran, it started working as a partner laboratory of the Standards Department. All products produced in Shahrokhi Technical Institute, including industrial dampers, and this product can perform various types of tests in the presence of supervisors and customers following standards 7693 and 7695 for pressure drop, throw length, flow distribution pattern, and other parameters.

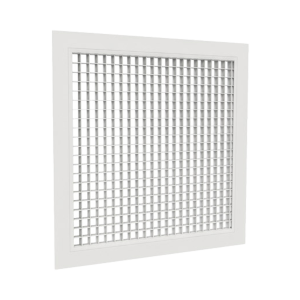

Installation location: inside the ceiling, wall, or open ducts

Material: Aluminum

Attributes:

Centralized air distribution with the ability to adjust in all directions

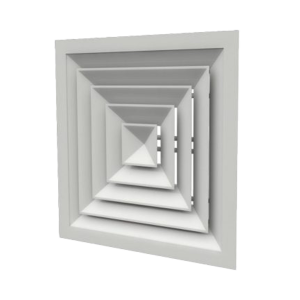

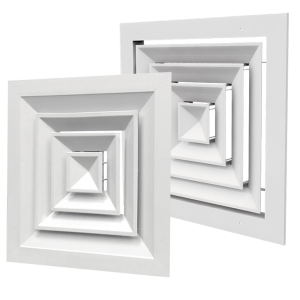

Placement in the frame in the types of one, two, three, and four elements

Aeration up to 8000 feet per minute

With square and round frame

Application:

Industrial environments

The halls

Stadiums

- Centralized air distribution with the ability to adjust in all directions

- Placement in the box in the types of one, two, three and four elements

- Aeration up to 8000 feet per minute

- With square and round frame

Attributes

- Industrial environments

- the halls

- Halls

- Stadiums