3D

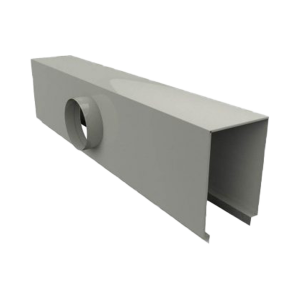

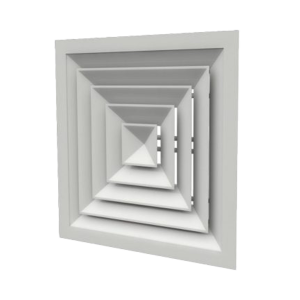

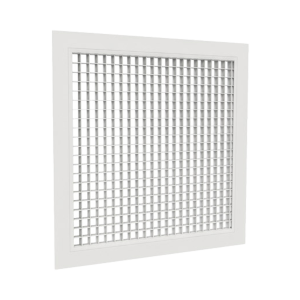

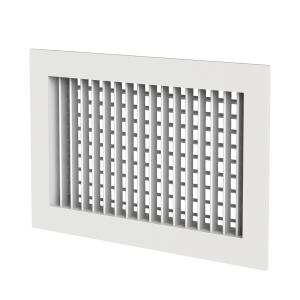

The two-way airfoil vane wall air valve, which is known as the cooler valve, is one of the most common types of valves in the ventilation industry. This valve is the most well-known type of valve among the general public, and the reason for its high use in the construction industry is its easy use and acceptable performance in air distribution and direction. These valves are mainly used for the inlet and outlet air vents of water coolers and air washers.

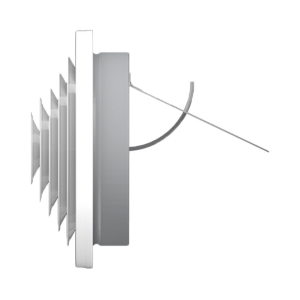

One of the advantages of this wall air valve (cooler valve) is the ability to change the direction of aluminum airfoil blades. which has the ability to adjust the flow direction in all directions due to its placement in two separate horizontal and vertical rows. Also, during production, according to the customer’s request, vertical and horizontal blades can be placed in the front or back row. The airfoil shape of the vanes of this valve, in addition to reducing the air pressure drop between the vanes, increases their efficiency in directing the passing flow. If required by customers, to control the volume of air entering the valve, dampers behind the parallel and opposite valve are used. There is also the ability to install the conversion of square to round to install the flexible channel behind the valves, as well as the implementation of coating in a variety of electrostatic powder furnace colors.

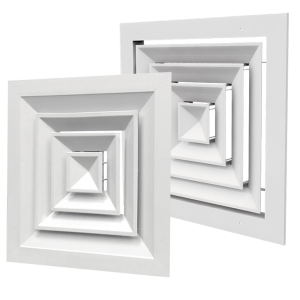

Consumables and materials and thicknesses:

The material of the blade and frame profile in this valve is generally aluminum profile with a thickness of 1 mm for the blades and 1.25 mm for the frame.

It is possible to produce these valves from black iron sheet or galvanized steel with different thickness or stainless steel, upon request.

The width of the shutter frame can be 3.3 cm or 4.5 cm of aluminum profile or any other size of black or galvanized iron.

Dimensional limitations of construction:

The maximum length is 150 cm

The maximum width is 150 cm

The minimum length is 15 cm

The minimum width is 15 cm

Accessories:

Damper behind the valve made of galvanized sheet, parallel PD model

Damper behind the valve made of aluminum profile 7 and 8 model OD

Automatic motorized channel damper MOSQPDTV model

Final coating:

Color: The default color of these valves is white electrostatic powder paint (RAL 9016). In case of request, it is possible to apply other colors by announcing the corresponding color resin. It should be noted that it is possible to provide the valve in an acid-washed form and without any color coating to the customer.

Anodized: These valves can be provided with anodized coating upon customer’s request.

Hot galvanized: It is not used for these valves.

Wood design cover: If requested by the customer, it is possible to provide wood design cover for these valves by sending a sample of the desired cover.

Installation method: The installation of these valves and all types of anti-explosive valves is done with self-tapping screws and on a wooden frame installed on the edge of the channel according to the shape. Since the purpose of installing these valves is to blow air and they are usually installed on the edge of the channel and on a wooden frame, therefore, it can be used on all types of ceilings such as plaster, cement, brick, wood, etc.

Installation requirements: Along with this valve, 4 screws related to the installation are provided along with screw heads to maintain the appearance of the valves. (Screws and screw heads are exclusively for valves produced by Shahrokhi Technical Institute.)

Necessary information to place an order:

The opening where the valve is to be installed

Air intake is necessary for the valve

The number of valves that can be ordered

International color code (RAL)

valve material

Required accessories

- A horizontal vane that provides the possibility of directing the air in a vertical direction.

- A vertical vane that allows the air to be directed in a horizontal direction.

- Relatively long throw of the valve in the case of proper selection and sizing, which can provide up to 12 meters of horizontal throw for these valves.

- Easy to install

- These valves can be provided to the customer along with potentiometer, thermostat and remote control.

Attributes

- Adjusting the direction of the outgoing air is manual and the vanes must be adjusted one by one by the user or operator.

- They are not suitable for high air flow speeds due to vibrations in the blades.

- In sizes with long length and small width, they are not shaped.