3D

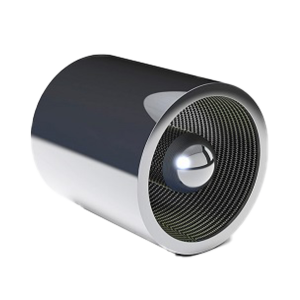

The square channel loudspeaker is one of the other flagship products produced by Shahrokhi Technical Institute. These silencers are designed and selected according to the existing sound level, the amount of sound absorption inside the channels and branches, the amount of sound absorbed in the environment and other factors of reducing the sound level. It is obvious that when the initial sound level produced by the fan of the ventilation device is not available, the experts of this institute get this level accurately using sound level analysis devices and based on that, they design the air duct noise reduction device.

The operation of channel loudspeakers

The basis of sound absorption in sound absorbers is based on the absorption of waves in porous materials. In such a way that the round channel silencer has parallel rows of sound absorbing materials that the waves moving along the channel are absorbed after hitting these sound absorbing walls. To increase the efficiency of this absorption, perforated metal sheets are used, which have a very high sound absorption coefficient. These perforated sheets, while directing the waves to the absorbing material, also dissipate the waves to a large extent.

The arrangement of perforated sheets and sound absorbent materials and air passage layers in a sequence creates specific paths of air passing through the absorbent materials, which achieves the lowest amount of flow pattern distortion and the highest amount of trapping of scattered sound waves. Normally, for each ventilation system, the sound production characteristics are extracted and announced, and according to the type of system, sound intensity, and air flow rate, a suitable silencer with a certain number of blades is designed and introduced.

Sound absorbing materials are of special importance as the main part of sound absorption in a sound absorber, while these materials should have special characteristics and special protective conditions due to health and environmental issues. In many cases, high resistance to heat, non-emission of toxic gases during fire, resistance to fungus and bacteria, and no dust formation in the ventilation system are considered to be the most important requirements of sound absorbing materials. In addition, in environments with special conditions, these restrictions may change to a large extent or be applied more strictly. What is common today in sound absorbers as sound absorbing insulators is the use of stone wool, glass wool insulators and polymer series insulators such as EPDM.

In the sound absorbers manufactured by this institute, the types of insulation mentioned above are used according to the specific sensitivities of the project or the special request of the customer or the internal design of the company, but normally this company uses compressed rock wool insulation for its sound absorbers, which while bearing Temperature up to 800 degrees is not a suitable substrate for the growth of fungi and bacteria due to its alkaline environment, so it is at an acceptable level from the point of view of health.

The only thing that should be considered in using this type of insulation is the use of dense coatings in the final layer of these insulations to prevent the release of insulation particles in the environment.

How the silencer works

Acoustic silencers, also known as dissipative silencers, use sound-absorbing materials to weaken the sound level. When the sound inside the air channel passes by the silencer, the sound energy or acoustic energy enters the silencer blades through the holes in the iron sheets of the silencer body. These perforated plates prevent the erosion of sound-absorbing materials at high speeds, and at the same time, due to the holes in the surface, they allow the passage of a large amount of sound energy, which is why they can be considered acoustically invisible.

Inside the muffler blade, the sound energy collides with the sound absorbing material, which is usually made of glass fibers. The friction between the sound energy and the glass fibers converts the sound energy into heat and reduces the sound energy and thus the sound level at the air outlet from the muffler. For silencers with high gap speed, a layer of glass fiber cloth is placed between the perforated iron sheet and the sound absorbing material to prevent blade erosion and wear. This fiber fabric has no effect on the sound absorbing power of absorbent materials.

It should be noted that the price of channel louvres and channel silencers is determined according to the quality of the product.

Maintenance and repair of square channel sounder

Sounders of Shahrokhi Technical Institute do not have moving parts and therefore do not need lubrication or maintenance.

In working conditions, if there are waste materials on the mesh surfaces, remove these materials from the surfaces using a damp cloth dipped in a cleaning agent.

Use cleaning materials that do not have a negative effect on the protective galvanized coating of steel sheets.

The presence of “white rust” on the galvanization of the silencer is a natural thing and is not an important issue in the maintenance issue. This problem arises when the zinc in the galvanization, which is used to protect the steel, reacts with moisture.

All loudspeakers have a solid body and are free of any defects. In order to ensure proper functioning, silencers should be visually inspected at least once a year and attention should be paid to the following:

The fins of the sound absorber are not damaged and are completely parallel in place.

Air passages between blades must be free of any obstructions.

The holes of the grid plates should be completely open and free of any dust.

Consumables and materials and thicknesses:

The material of the main body of the silencer is usually selected from aluminum sheets with a thickness of 1.25 to 2 mm according to the dimensions of its construction.

Except for the main body, each blade it has an internal skeleton that can be selected from 20*20*2 iron angle, 4*40*40 or 20*20*2 mm iron can depending on the dimensions of the blade.

Perforated sheets covering the blades are usually selected from 1.25 mm aluminum sheet or 1 mm galvanized sheet.

Conductor sheets are usually selected from galvanized sheets with a thickness of 1.25 mm or aluminum sheets with the same thickness.

The sheets of floor rails are usually selected from galvanized sheets with a thickness of 1.25 to 3 mm.

Dimensional limitations of construction:

This product does not have a special limitation in dimensions for manufacturing, considering that in very large sizes, the main metal body of this product is removed from the walls of the space for its installation. Therefore, there is no special limit for the dimensions of this product.

Final coating:

Color: For this product, electrostatic paint can be applied only on the metal skeleton of the vane to prevent rusting if requested by the customer, and other components will not rust due to the material.

Anadize: It is not used for this product.

Hot-dip galvanized: It can be applied in the case of metal frame upon customer’s request.

Installation method: Sound absorbers are installed in the space in two ways:

The first case is when the silencer is designed and built as an inter-channel member, in which case its area is at least 1.5 times the cross-sectional area of the channel. In this case, the installation of the silencer is done using 2 conversions on both sides and by means of flanges, and fireproof thread is used to seal the flanges.

The second case is when the silencer is installed in the air inlets and outlets of the fan rooms, in which case there is no interface channel and the silencer is fixed to the walls, ceiling and floor.

Installation requirements: To install a channel silencer, it is enough to use bolts and nuts to close the flanges, but in the case of larger silencers, it is necessary to use concrete screws and even welding to secure the rails and supports.

Necessary specifications to place an order for a channel sounder:

Type of ventilation system fan (to estimate the sound level produced by it)

fan power

around the fan

Type of space use

The area of the ventilated space

The material of the walls of the space to be ventilated

Type and average dimensions of channel branches

Type of channels (round or square)

The length of the channel to the first consumer

Safety and health requirements of the ventilated space

Schematic map of the channel system or room space for ventilation equipment

- Design and construction based on the tables and standards of the world

- Using all kinds of sound absorbing materials according to the customer's request

- Using a solid body for maximum resistance to air currents

- No restrictions on manufacturing even in very large dimensions

- Modular design with the ability to move the blades

- Minimum pressure drop due to the use of flow conductor plates

- Ease of installation and operation

- The size is at least 1.5 times the main section of the channel, which is considered to prevent the increase of air speed and the creation of additional noise.

- Moving the air flow directly to increase the flow rate and reduce the pressure drop.

- Hard rounded tip to maximize noise reduction.

- Round inlet to reduce disturbance, pressure drop and sound produced by the silencer.

- Without any protrusions to eliminate disturbances and noises produced in the speaker.

- Having hard surfaces in the place of air passage and minimizing the amount of pollution accumulation.

- Corrosion protection of sound absorbing materials by mesh sheets.

Attributes

- In air conditioning channels, generally due to fan operation, whether axial fans or centrifugal fans, an unpleasant sound is scattered in the ventilated environment, and the intensity of this sound depends on various factors such as the type of fan, the distance of the fan from the location, the type and type of channels and Branches, the type of walls and other such factors are different, but in any case, the presence of these sounds will create an uncomfortable environment for the residents.

- Today, in the world, they use channel silencers to solve this problem. These silencers with a special design, in addition to minimal impact on ventilation air flow, eliminate the sound produced by air conditioners to a very high extent.

- The material and design of these silencers are such that they absorb sounds produced with all kinds of frequencies and in the range of human hearing (from 63 to 8000 HZ) they provide comfortable environmental conditions in terms of sound. In this regard, the design of a sound absorber that can provide these conditions in the environment is of special importance, in the case of an incorrect design, the sound absorber will not only not be able to absorb sound, but as the factor that creates sound, it will double the problems. made