3D

In general, all mechanical devices that are installed under the false ceiling of the building, need a door to visit and access for periodic services or repairs. Therefore, inspection doors are used to access these equipments. The aluminum fan coil inspection door is used for ventilation devices such as fan coils and duct splits.

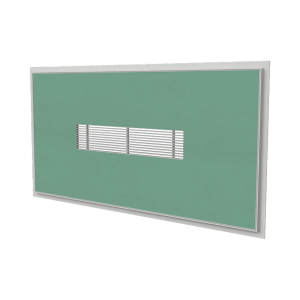

If the return air suction of these devices is through the return channel, these inspection doors do not need a grill or groove, but if the return air suction is from under the device, the inspection door needs a grill or groove. For these cases, Shahrokhi Technical Institute offers different solutions in different models.

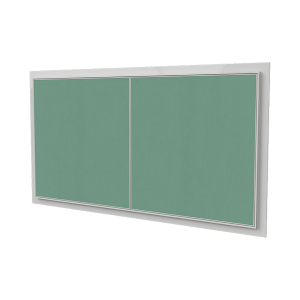

Fan coil inspection doors are divided into two general categories: Siemens lock and weighted fan coil inspection doors. In the lock and hinge models, grills are not considered by default, but there is the ability to add a mesh grill with linear valves and an egg basket valve on them. Weight models are also divided into two single-groove and two-groove products, which are selected according to the ventilation rate of the device and decorative taste. In these models, the door is separate from the valve frame and the door is placed on the frame as a weight.

Single-groove and double-groove opening under the fan coil valve are also produced by combining two models of weight and lock and hinge. This model is used when the distance from the ceiling to the device is not enough and it is not possible to separate the weighing inspection door. Therefore, both the beauty of single-slot and double-slot inspection doors is achieved, and the limitation of the space above the inspection door to the machine is eliminated.

Final cover and valve installation under the fan coil

Like most of the valves produced in this collection, an automatic screw is used to install this product, and instead of a screw (treasure), it is created before applying the color coating